Robot Integration & Packaging

Home » What We Do » Robot Integration & Packaging

- Automation

- Robotics

- Workholding

- Build to Print

- Consulting

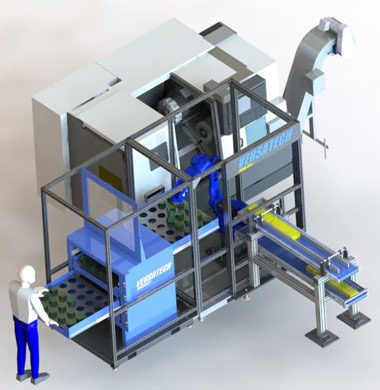

Versatech understands the difference between textbook engineering and common sense engineering and we rely heavily on the common sense engineering approach to robotic integration solutions that are robust and reliable in real world applications. As a machine integrator, we utilize robotic integration, automation, and controls hardware with proven software controls and programming. We design and build automated and robot integrated assembly and testing systems that ensure our clients the capability to reach their production and efficiency goals. A robotic cell helps manufacturing prepare for the future.

Visit our Technology page to review a sampling of the many controls & programming systems that we currently utilize

Some standard Robotic Assembly Solutions:

- Screw install/driving

- Clip install

- Standard pick and place

- Dispensing (adhesive, lube, etc)

- Vision system integration (Keyence or Cognex)

- Ultrasonic cutting

- Integration with covenyors or indexers

- Integration with various PLC’s and HMI’s

In conjunction with robotic machine tending, Versatech can provide complete turnkey equipment:

- Hydraulic machining center integration

- Fixture design and fabrication

- Material handling

- Cutting tool and process validation support

Versatech can combine part inspection or part locating with almost any robot.

Do you have a difficult or large part that needs inspection? Mount a camera on the end of a robot arm and allow the robot and vision system to complete the inspection process!

Do you have a process that requires a part to be located and then brought the next process? Apply a vision-guided robot!

Versatech is a certified Keyence and Cognex vision integrator.

Versatech will design, fabricate, and integrate tooling for new or existing robots. Some common solutions include:

- Custom Pick & Place Tooling

- Pneumatic Grippers

- Vacuum + Suction Cup Systems

- Explosion Proof Systems

- Vision Systems (Keyence or Cognex)

Versatech can configure robotic packaging solutions for your case packing or palletizing process. Whether you need to build a box, put product into a box, or place the box onto a pallet or need a solution to do all three, Versatech has engineered a system to match your requirements.

Case Packing:

- Rapid pick and place motion

- Can be integrated with vision for 100% product inspection prior to packaging

- Pick from moving conveyor with vision part location

- Robotic packaging for consistent quality

Palletizing:

- User-friendly robotic palletizing software

- Robot payload capacities range from zero to 1325 lbs.

- Various robot tooling options & configurations – suction cup, pneumatic grippers, etc

Collaborative Palletizing Cell:

- Dual-pallet loaders for non-stop production

- Servo controlled vertical movement for extended pallet heights

- Up to 17-pound payload (with standard option)

- 6-8 picks per minute (in collaborative mode)

- Can be customized to your specifications

- Compact footprint

- Robust for industrial use. HD steel frame.

Robotic Box Erector:

- Tape, glue, & staple options for closing boxes.

- Simple mechanisms for increased longevity.

- Robot custom end of arm tooling to secure and hold boxes square

- Accommodate many box sizes large and small.

- Collaborative options available.